Custom Pizza Boxes

- Experienced Staff

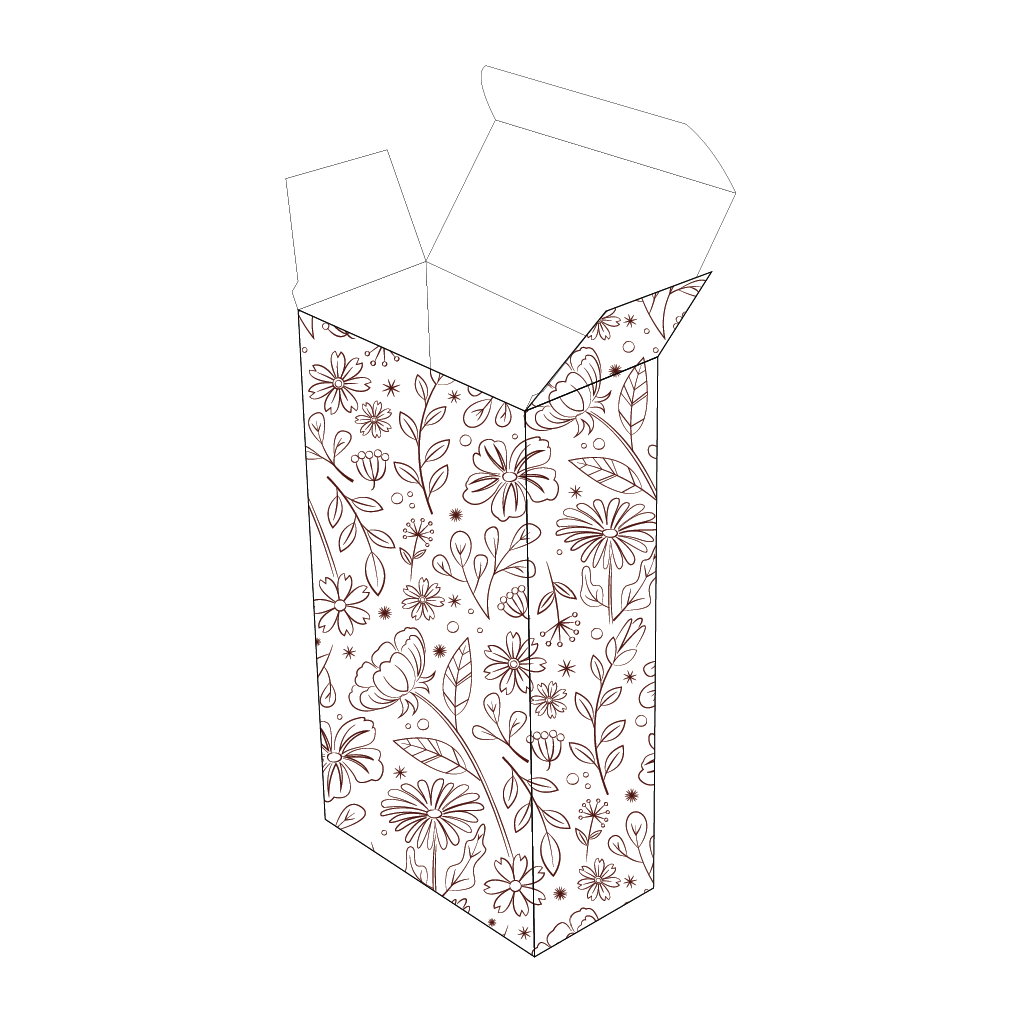

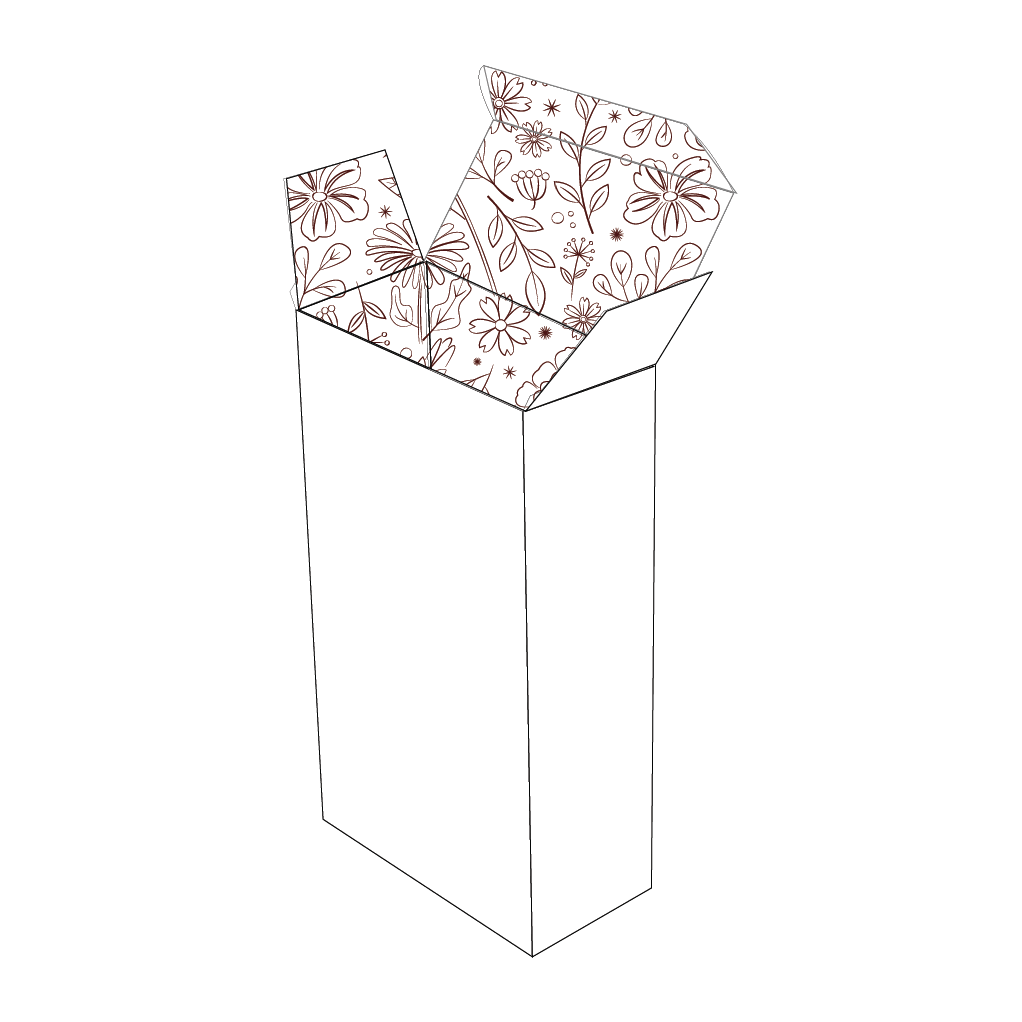

- 2D/3D Studio

- Quick Turnaround

- No Die & Plates Cost

- No Setup Fee

- Express Delivery

Pizza is famous all over the world as people love to eat it. Most of them will like to eat pizza when hot; otherwise, it loses all the taste and charm. The fast-food chains know that if they don’t offer good quality pizza, no one would like to purchase them. There are many ways in which they keep the pizza warm when delivered to the customer. Some people like to eat pizza in the restaurant while others like it as a takeaway or even call for a home delivery service.

No matter what, they will want the pizza to be hot and tasty. The packaging shouldn’t affect the pizza quality, or else it can affect the sales drastically. Pizza Boxes that are made up of cardboard are trendy among food brands. They are useful in keeping the high quality and warmth of the pizza. The taste of cold pizza will get deteriorated no matter how good the ingredients are. Here is how you can store pizza in hot condition with the best box packaging.

Mini cardboard pizza boxes to impress your customers:

The fast-food chain owners know that it is essential to check the boxes’ materials before they think about packing their pizza inside. It will keep the pizza fresh and healthy as well. Your consumers will like it when they know that you think about their health and security. It is not an easy task to impress your targeted customers. Packaging plays a vital role in determining sales, and several things must be done to achieve the best of results.

Your customers will like it when you use good pizza packaging designs and decorate them nicely. If your restaurant is making a delivery to the customer’s houses, well-designed packaging is even more critical. Materials like cardboard and Kraft will keep the pizza safe and won’t let any harmful element enter the box. The cardboard pizza box is made of eco-friendly materials, which is another reason why your customers will be impressed. The corrugated boxes designed for dining purposes are a lot different from those used for delivery purposes.

Pizza boxes to keep pizzas warm and fresh:

Pizza boxes Australia is a perfect choice for delivery purposes. They are strong enough to maintain the weight of the pizza. Additionally, they will keep the moisture away and prevent the pizza from getting soggy, which can deteriorate the taste. There are some cheap pizza boxes, but they cannot be used only for small distances due to a lack of durability. The corrugated pizza boxes can keep the food warm and safe for a long time.

The cheese topping on the pizza will remain in good shape if the boxes can keep it secure. The boxes that are used for pizza must be highly resistant and thermally insulated so that they can regulate humidity. The food restaurant owners also use quality printing on the box to print their logo and restaurant’s name. It will help the customers recognize them among a vast crowd and increase their sales. If the boxes have holes for ventilation, it is good to keep them away from sogginess. Pizza boxes have a coating of aluminum foil that can retain heat and keep the condensation inside.

Food-graded pizza packaging:

Food-graded pizza packaging is a perfect packaging solution for pizzas that have been tested by the food authorities. The pizza box manufacturers try the packaging differently to make sure it will be the right choice for different pizzas types. It will keep the pizza fresh, healthy, tasty, and safe. When the packaging design passes all the tests, it is referred to as food-grade packaging. One of the main things that the pizza sellers focus on is the recipe because everything is useless without good taste. They want to use the best ingredients and make delicious pizzas meaningful for the business to succeed.

Fortunately, if you get in touch with the right pizza box supplier, they will help you out by manufacturing some quality boxes for storing pizzas. If the manufacturers have much experience working with the food industry for ages, they can never go wrong. They know what the fast-food brands and their targeted customers will demand, and catering to their needs is their priority. The cheese topping on the pizza has a delicious and creamy taste. Without it, the pizza remains incomplete. There are different types of pizza, but the one with chicken is the most popular among people. It is observed that people of all ages love it, but kids get very excited at the sight of a pizza.

Pizza boxes of different shapes and sizes:

The best thing about pizza boxes wholesale is that they are available in different shapes and sizes. The pizza sellers can store any pizza inside without any worries. If the boxes are ordered in bulk, they will get discounts. Custom pizza boxes have their charm as they look visually appealing, and necessary information can be printed on them with vibrant colors. It is easy to print mouth-watering pictures of pizza and the restaurant’s number on the top of the box. No matter what country you are traveling to, there is one typical food that everyone loves.

If the packaging designs are not impressive or the boxes cannot keep the pizza’s hotness and quality intact, forget about increasing sales.

The food industry depends a lot on pizzas sales as it helps them earn a considerable amount of money. If the box remains closed, there are chances that it will keep the pizza warm, but the moisture will ruin the crust. The box should have proper insulation and venting so it can keep the pizza fresh. Nowadays, most of the boxes come with easy recycling or are equipped with holders used for dipping sauces. The customers can quickly transform them into plates. Fortunately, Boxes Expert is manufacturing durable boxes for pizza transport situations. It will instantly increase sales too.

| Box Style | Tuck Flap Box, Pillow Box, Sleeve Box, Gable Box, Punch Partition |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround Time | |

| Standard Turnaround Time: After the client’s approval of the artwork and once the payment is placed, we will send the job to production. Usually, it takes 10 – 12 business days for the production and then 5 – 6 working days to ship the boxes. While the turn-around time for the corrugated boxes/shipping boxes is 15 – 20 business days, and then it takes 5 – 6 business days to ship these boxes to your doorstep. In the case of Rigid Boxes, the turn-around time is increased up to 25 – 28 business days and then 5 – 6 business days to ship them. | |

Rush Delivery Services: We always try to deliver the boxes within our turn-around time, but if you need the boxes on an urgent basis, we also offer Rush Delivery Services, which may cost you extra charges. But we charge Rush Delivery Services charges less than the competitors in the market | |

| Shipping | Ship Flat, Packed in Boxes, UPS, FedEx, DHL |

If your artwork doesn’t meet our specifications, Boxes Expert will not be charged for any graphical errors. Please look at our artwork preparation guidelines to prepare your artwork files for submission, or say hi to our Expert Design team.

Cut & Crease Line (Red Lines):

Red lines display the section’s final size and where the box will be folded. Illustrations and text should be set up at least 0.125 inches away from the cut line.

Bleed Line (Blue Lines):

Bleed lines show the location of the drain section. In order to get the transparent print, all the graphics should be extended to the cut line.

Safety Margin (Green Lines):

Safety margins ensure the safe placement of the illustrations and text. According to the industry standards, all the Illustrations and text should be set up at least 0.125 inches away from the cut line.

Perforation (Dotted Black Lines):

A black line specifies the perforation line. Perforation refers to paper punched where small holes are made, which make it easier to tear and fold the box

Artwork Acceptable formats

Artwork acceptable formats are;

- Adobe InDesign

- Adobe Photoshop

- Adobe Illustrator

- Corel Draw

Artwork Creation Guidelines:

Place the artwork of your brand on the provided template and then provide it to us for proofing.

If you need white ink for your product then please make a separate layer for that

The minimum resolution for the image (you want to imbed) should be 300dpi or you have to provide a vector file.

Color Management:

TO match the PMS, identify the colors on the file, please.

The colors on the pdf file are not compatible with the original paints, so it is advised not to decide on colors from the pdf.

If you already have the color samples then share them with us, so that with the help of our design team we match the colors.

Fonts:

If there are special fonts used in your file then curve outline them.

Special fonts utilized in the file are to be provided separately.

Page Size:

Setup the size of pages of your artwork to the same size as the file on a single page.

The design team in our facility will adjust the artwork canvas and upping.

Ensure the size of your box by printing the final proof on the actual size and then make the paper dummy, so that you have a perfect idea about the sizing of the box.

Choose Your Box

Select the style of the box from our library of custom cardboard boxes, corrugated boxes, and many other custom printed products suitable for your project. Add your favorite products with all the custom sizes and options to track what fascinates you. You can submit the quote request to start your packaging journey when you are done with the selection. However, if you can’t find what you were looking for in our library, you can visit our GET A QUOTE pages and submit a custom quote.

Send a Quote Request

After you have sent your quote request by our Request a quote page with all your product specs, our specialists will start working on your quote. The quote can be ready and sent to you within 24 hours. But for the custom structural or material box, it may take longer. A dedicated product specialist will reach out to you and will be connected to you throughout the complete process.

Place Your Order

Once you receive the price quote, please review it to ensure that all of your quotation details are correct, and if you have any questions about your offering, please feel free to contact our product specialist. After the confirmation, you can place your order. As you place the order, then our design team will quickly prepare your dielines.

Get Your Custom Dielines

After you make an order, then place your artwork on the dielines. In the case of a single floorboard, our design team can prepare your file in 24 hours. Usually, our dieline file contains structural information, which can be converted into a 3D digital model after you place the artwork on the file. In this way, you can preview and make necessary changes to your packaging before production starts.

Prepare Your Artwork

Prepare your artwork design, or you can take the help of our experts. Make sure that the artwork is according to our Art Work guidelines. When your graphic is ready, upload your file. Our specialist graphic designer will review your design and create a 3D model of your packaging before production starts.

Production Starts

Once you’ve approved everything, we will send your packaging project to production. Our product specialist will keep in touch with you during this entire process and provide production and shipping updates.

How to Measure Box & Packaging Dimensions

Box size includes length, width, height, and depth, which can technically mean commodities different to everyone. To ensure we know precisely which sides of your packaging box do have the; we’ve created these dimensions guidelines for accessible communication for our clients.

Note:

Packaging Designs dimensions are defined as length x width x height. For example, 12″x 07″x 2″means 12″ (L) x 07″ (W) x 2″ (H)”.

If you have any issues, please give us a call so we would love to elaborate precisely.

Printing Options

4/4 Printing

Full Colour Inside Outside

4/0 Printing

Full Colour Outside Onlye

0/4 Printing

Full Colour Inside Only

0/0 Printing

No Printing

Call us We'll respond to you!

Frequently Asked Questions

We are providing expert packaging solutions to our clients globally. We are dealing with Digital, Offset & Screen Printing.

If you change in quantity, we’ll go with the same design and our previous working strategy, but the price varies slightly. If you made any changes in design/artwork after processing the printing process, you might be charged with a new estimated amount.

Our standard lead time is 12 – 14 business working days for the production time. Our Rush Orders usually take 6 – 8 business working days for production.

We also supply physical samples with a nominal sampling fee, and We do not charge sampling charges on bulk quantity.

Once you have placed your order, you should get proof within 1 – 3 business days after receiving your electronic files.

Yes, we offer Free Design Support & Digital Proof (2D & 3D) to conjure what the actual outcome will look like, and we also deliver physical samples.

We provide our services globally; we deliver customized boxes at our client’s doorstep.

Our shipping department is confident in providing hassle-free shipping, but if there are any mishaps, we’ll give the damaged quantity (in some cases).

We are always tried our best to meet the client’s deadline, and we are dealing with DHL, FedEx & UPS.

Yes, we would love you facilitate you with good discounted numbers.