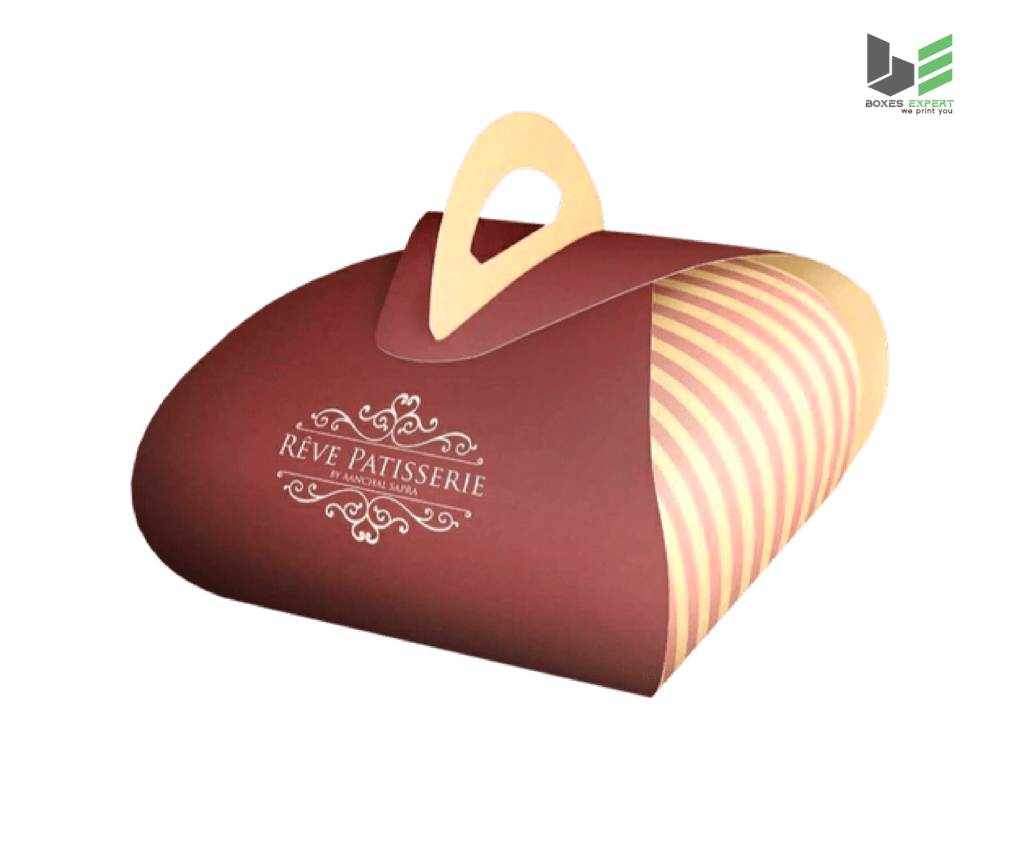

Custom Donut Boxes

- Experienced Staff

- 2D/3D Studio

- Quick Turnaround

- No Die & Plates Cost

- No Setup Fee

- Express Delivery

Donuts Needs To Be Handled With Care While The Transit Process Keeping Chocolate Or Other Coated Things. Donut boxes are used to provide your different bakery products like cakes, donuts, sweets, and pastries with extraordinary preservation and fine quality protection. This product protection is why most bakery product manufacturers utilize their features to gain maximum growth in a short period. With high-quality materials, the finest finishing qualities, and amazing designs, they contain everything. They hold several protection functionalities in them; some of the best are given below.

Keep the product safe:

To keep your customer satisfied, it is necessary to provide donuts in their perfect form to enjoy their taste easily. It takes a long time for a business to maintain its reputation; if the slightest change in the product’s quality occurs, the business can lose its reputation. Product protection is one of the most important factors to maintain in business strategies. Buying donut boxes wholesale in bulk amounts can keep the protection need of your business up. High-quality corrugated and kraft papers and materials are used to produce these packages. With their durability, you can manage the distinctive need of your customer easily. Go for different online stores that produce these packages and buy them as much as possible because they are also cost-effective. Your customer will always look out for you whenever he needs safe and fresh donuts, sweets, cakes, and pastries if you use this packaging to present your bakery items.

Long shelf life:

You have seen some packages with exhaust holes in them; they release steam them. But in selling donuts, you have to choose packaging without those holes so that your product’s shelf life can be increased. Custom donut packages are the packaging solution that can do that for your product easily. They provide airtight preservation so that your donut would not spill out its cream or chocolate and make a mess inside so that your customer can have a perfect and clean delivery. Donuts have the nature that if they get fresh air, they tend to dry out quickly and become tasteless. That is why it is necessary to seal your donut packages perfectly; this will also help them be safe from other elements like bacteria, dust, and water. By this, you are not just securing your delicate bakery products but can also secure many satisfied customers for your business. From this, you can get that they are not just to improve your product’s shelf life but also increase the longevity of your business.

Laminations:

From a specific amount of wear and tear, you can protect your printed donut boxes through different laminations and coating techniques. These are not just to make the package durable from the outside; you can use it inside them to save your products from different product-harming elements. This will increase your box’s longevity, and your delicate donuts can be stored in them for a long time. Die-cutting finishing techniques will allow you to provide every customer with a box of the same size and shape. Rather than using cost-effective lamination techniques, you can utilize finishing and coating like matte, gloss, and ultra-spot UV according to your preference, need of a product, and budget. These coatings will help you to make the walls or sides of the packages resistant so that the cream or chocolate on your donuts would not get disturbed if they hit the walls. The shiny surface that you get from these coatings will make the presentation of your bakery products cleaner and more attractive while protecting your product from getting any bacteria and contamination.

Safe delivery:

Maintaining your delivery service will help you in making your business a reliable one in the market. Having good control over the delivery process and providing the product safely to your customer is the most important need and factor for every business. These boxes will help you to improve the efficiency of your business. Donuts usually come in delicate creamy shapes, which is why you need to take every single precautionary measure to provide your customer with safe and sound delivery. Several layers of kraft, corrugated, and cardboard paper are utilized to manufacture donut boxes in Melbourne, which is why every bakery product manufacturer keeps them on their priority list while delivering their products. With their thickness, they can bear the heavyweights of other packages on them during delivery. Your business will expand because of the safe and timely shipment or delivery, and you can earn a number of potential customers for your bakery store.

Temperature resistant:

Donut box packaging is usually made up of different layers of kraft and corrugated paper layers. That is why they have thicker sides than any other packaging solutions. These packages’ thickness helps them maintain the temperature inside the box and keep your donut fresh. Donuts are edibles that need proper preservation in which they can remain for a long time without lessening their taste and flavor. To maintain the taste, you have to provide a solution in which the box’s temperature can remain stable throughout the delivery process. You can use this temperature, maintaining nature to preserve your other bakery products in the donut box as well. Your customer would not buy from you again if you deliver the donut in a messy shape and spilled cream all over the package. That is why it is necessary to utilize the thickness of these packages to keep your donuts safe from getting moisture and losing out the cream or chocolate placed on top of it.

With the protection of donut boxes, you can easily outrank your rivals in the market. The protection you provide can be the reason for customer trust and satisfaction growth in your business. Your customer would call you every time whenever he requires safe and fresh donuts. Not just protection, you can bring several advantages to your business by using this packaging solution.

| Box Style | Tuck Flap Box, Pillow Box, Sleeve Box, Gable Box, Punch Partition |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround Time | |

| Standard Turnaround Time: After the client’s approval of the artwork and once the payment is placed, we will send the job to production. Usually, it takes 10 – 12 business days for the production and then 5 – 6 working days to ship the boxes. While the turn-around time for the corrugated boxes/shipping boxes is 15 – 20 business days, and then it takes 5 – 6 business days to ship these boxes to your doorstep. In the case of Rigid Boxes, the turn-around time is increased up to 25 – 28 business days and then 5 – 6 business days to ship them. | |

Rush Delivery Services: We always try to deliver the boxes within our turn-around time, but if you need the boxes on an urgent basis, we also offer Rush Delivery Services, which may cost you extra charges. But we charge Rush Delivery Services charges less than the competitors in the market | |

| Shipping | Ship Flat, Packed in Boxes, UPS, FedEx, DHL |

If your artwork doesn’t meet our specifications, Boxes Expert will not be charged for any graphical errors. Please look at our artwork preparation guidelines to prepare your artwork files for submission, or say hi to our Expert Design team.

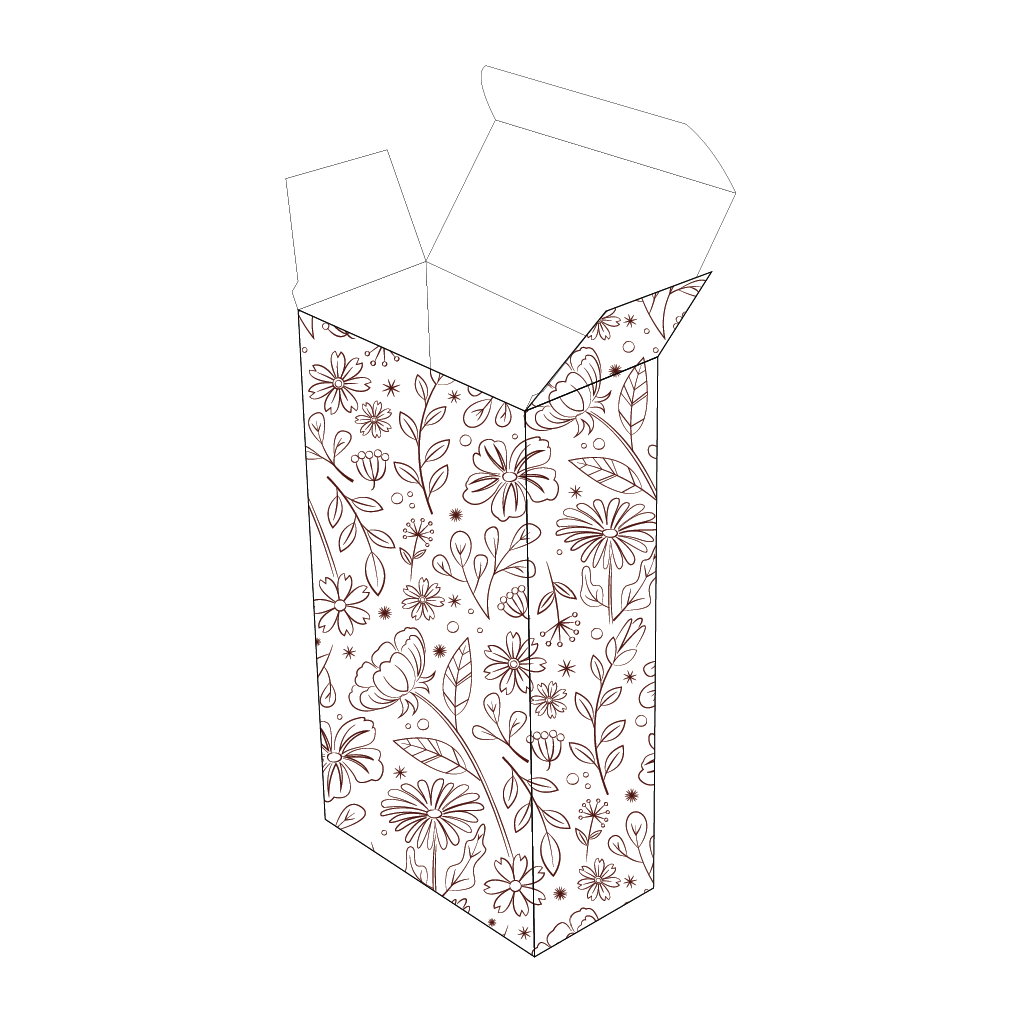

Cut & Crease Line (Red Lines):

Red lines display the section’s final size and where the box will be folded. Illustrations and text should be set up at least 0.125 inches away from the cut line.

Bleed Line (Blue Lines):

Bleed lines show the location of the drain section. In order to get the transparent print, all the graphics should be extended to the cut line.

Safety Margin (Green Lines):

Safety margins ensure the safe placement of the illustrations and text. According to the industry standards, all the Illustrations and text should be set up at least 0.125 inches away from the cut line.

Perforation (Dotted Black Lines):

A black line specifies the perforation line. Perforation refers to paper punched where small holes are made, which make it easier to tear and fold the box

Artwork Acceptable formats

Artwork acceptable formats are;

- Adobe InDesign

- Adobe Photoshop

- Adobe Illustrator

- Corel Draw

Artwork Creation Guidelines:

Place the artwork of your brand on the provided template and then provide it to us for proofing.

If you need white ink for your product then please make a separate layer for that

The minimum resolution for the image (you want to imbed) should be 300dpi or you have to provide a vector file.

Color Management:

TO match the PMS, identify the colors on the file, please.

The colors on the pdf file are not compatible with the original paints, so it is advised not to decide on colors from the pdf.

If you already have the color samples then share them with us, so that with the help of our design team we match the colors.

Fonts:

If there are special fonts used in your file then curve outline them.

Special fonts utilized in the file are to be provided separately.

Page Size:

Setup the size of pages of your artwork to the same size as the file on a single page.

The design team in our facility will adjust the artwork canvas and upping.

Ensure the size of your box by printing the final proof on the actual size and then make the paper dummy, so that you have a perfect idea about the sizing of the box.

Choose Your Box

Select the style of the box from our library of custom cardboard boxes, corrugated boxes, and many other custom printed products suitable for your project. Add your favorite products with all the custom sizes and options to track what fascinates you. You can submit the quote request to start your packaging journey when you are done with the selection. However, if you can’t find what you were looking for in our library, you can visit our GET A QUOTE pages and submit a custom quote.

Send a Quote Request

After you have sent your quote request by our Request a quote page with all your product specs, our specialists will start working on your quote. The quote can be ready and sent to you within 24 hours. But for the custom structural or material box, it may take longer. A dedicated product specialist will reach out to you and will be connected to you throughout the complete process.

Place Your Order

Once you receive the price quote, please review it to ensure that all of your quotation details are correct, and if you have any questions about your offering, please feel free to contact our product specialist. After the confirmation, you can place your order. As you place the order, then our design team will quickly prepare your dielines.

Get Your Custom Dielines

After you make an order, then place your artwork on the dielines. In the case of a single floorboard, our design team can prepare your file in 24 hours. Usually, our dieline file contains structural information, which can be converted into a 3D digital model after you place the artwork on the file. In this way, you can preview and make necessary changes to your packaging before production starts.

Prepare Your Artwork

Prepare your artwork design, or you can take the help of our experts. Make sure that the artwork is according to our Art Work guidelines. When your graphic is ready, upload your file. Our specialist graphic designer will review your design and create a 3D model of your packaging before production starts.

Production Starts

Once you’ve approved everything, we will send your packaging project to production. Our product specialist will keep in touch with you during this entire process and provide production and shipping updates.

How to Measure Box & Packaging Dimensions

Box size includes length, width, height, and depth, which can technically mean commodities different to everyone. To ensure we know precisely which sides of your packaging box do have the; we’ve created these dimensions guidelines for accessible communication for our clients.

Note:

Packaging Designs dimensions are defined as length x width x height. For example, 12″x 07″x 2″means 12″ (L) x 07″ (W) x 2″ (H)”.

If you have any issues, please give us a call so we would love to elaborate precisely.

Printing Options

4/4 Printing

Full Colour Inside Outside

4/0 Printing

Full Colour Outside Onlye

0/4 Printing

Full Colour Inside Only

0/0 Printing

No Printing

Frequently Asked Questions

We are providing expert packaging solutions to our clients globally. We are dealing with Digital, Offset & Screen Printing.

If you change in quantity, we’ll go with the same design and our previous working strategy, but the price varies slightly. If you made any changes in design/artwork after processing the printing process, you might be charged with a new estimated amount.

Our standard lead time is 12 – 14 business working days for the production time. Our Rush Orders usually take 6 – 8 business working days for production.

We also supply physical samples with a nominal sampling fee, and We do not charge sampling charges on bulk quantity.

Once you have placed your order, you should get proof within 1 – 3 business days after receiving your electronic files.

Yes, we offer Free Design Support & Digital Proof (2D & 3D) to conjure what the actual outcome will look like, and we also deliver physical samples.

We provide our services globally; we deliver customized boxes at our client’s doorstep.

Our shipping department is confident in providing hassle-free shipping, but if there are any mishaps, we’ll give the damaged quantity (in some cases).

We are always tried our best to meet the client’s deadline, and we are dealing with DHL, FedEx & UPS.

Yes, we would love you facilitate you with good discounted numbers.